R.C. TECHNOLOGY

RAMLA CONSTRUCTION TECHNOLOGY

مؤسـسة الرمـــــلة لتقــنية البناء

" Your Partner in Success "

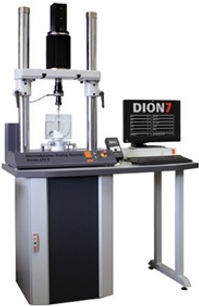

Dynamic Multipurpose Testing System

Our Products

Series LFV-E(1-2.5 KN)

Series LFV-E(1-10 KN)

Series LFV-E(10-100 KN)

Series LFV-E(100-1000 KN)

Series LFV-E(63-600 KN)

Series LFV-L(1-2.5 KN)

Series LFV - T

Series LFV - E 1 - 2.5 kN

State-of-the-art ServoElectric testing system to execute both static and dynamic testing on materials and components including biomaterials and biomedical / dental implants, plastics, textiles composites and automotive or electronic components.

Electrodynamic Testing Systems

The Series LFV-E are fluid-free non-hydraulic systems currently available with force capacities up to 2.5 kN for fatigue and durability testing, tensile, compression, bend, peel or shear strength testing as well as crack initiation. These table top systems with its Servo Electric drive mounted on upper crosshead represents a versatile and reliable fatigue rated testing machines combined with latest drive technology. These machines are selected from testing professionals in quality control, R&D or Universities who desire a compact space saving, clean and quite low force testing unit that requires no environmental consideration and virtually no maintenance. The ServoElectric drive with its in-line digital displacement transducer provides noise-free stroke measurement or control. This drive features backlash-free motion with no fluid compressibility to compromise position accuracy. The system is available with integral T-slot platen providing high degree of flexibility or attachable (to the upper crosshead) closed frame often used from those who test e.g. dental implants in combination with saline bath. The upper crosshead can be lift or lowered through integrated electrical spindles to adjust the desired test space. Only unclamp the crosshead by twisting the lever clamps and pushing the up / down bottom without any tools. The spindles for lift/lower are protected against dust or mechanical damage. An emergency stop is available direct at the testing machine as well as on the remote control unit which can be used for precise of the actuator through digital hand-wheel.

Specially designed for fatigue testing of low strength materials such as biomedical implants and dental implants as well as plastics, aluminum, elastomers, components and finished goods.

The upper crosshead features the innovative electrical height adjustment for quick and accurate positioning for test set-up.

Compact Low-Force Dynamic Testing Systems

This multipurpose dynamic testing system features the innovative electrical height adjustment for quick and accurate positioning of the upper crosshead for different sizes of specimens and different testing devices. Also a salt bath for testing of implants in salt solution up to 37° can be mounted into the machine. The bath can easily be moved in and out of the testing chamber.

Features

-

Rigid two-column construction

-

Precision aligned

-

Equal area actuator with hydrostatic bearings mounted on top of crosshead

-

Manifold is attached direct on actuator providing close-coupled servovalve and accumulators for improved performance and reduced pressure fluctuations

-

Upper crosshead adjustable to facilitate repositioning.

-

Columns are chrome plated and hardened for easy cleaning and longest life

-

Precision flat load cell mounted on piston rod end.

-

Integrated displacement transducer

-

Compression platens, bending or folding devices may be fixed directly into wedge grips or backlash-free washers.

Specially designed for fatigue testing and research of biomedical implants, advanced materials, components, manufactured assemblies or finished goods. The crosshead features automatic adjustment with hydraulic unlocking and hydraulic moving through two long stroke actuators.

Compact Dynamic Testing Systems

These compact testing systems have the hydraulic power pack integrated in the base of the machine. These machines are self-contained, stand-alone units. The actuator is mounted on the upper crosshead. The machines are equipped with integral T-Slot platen suitable to fix components, specimens or manufactured assemblies. The standard model features the hydraulically moveable crosshead with passive clamping for an easy and accurate positioning of the upper crosshead.

Features

-

Rigid two-column construction

-

Precision aligned

-

Equal area actuator with hydrostatic bearings mounted on top of crosshead

-

Manifold is attached direct on actuator providing close-coupled servo valve and accumulators for improved performance and reduced pressure fluctuations.

-

Upper crosshead hydraulically adjustable to facilitate repositioning.

-

Columns are chrome plated and hardened for easy cleaning and longest life

-

Precision flat load cell mounted on piston rod end.

-

Integrated displacement transducer.

Versatile servohydraulic testing systems for higher capacity applicable for the fully spectrum of static and dynamic testing. The actuator is mounted on upper crosshead and the lower platen can be supplied with T-Slots for the ultimate flexibility.

Multipurpose Dynamic Testing Systems

The cylinder of this Series LFV is mounted on the upper crosshead. The power pack is a freestanding unit and can be placed in a separate room. The machines can be equipped with integral T-slot platen suitable to fix components, specimens or manufactured assemblies. The machine can be configured with climatic chambers, high temperature furnaces, testing devices and other accessories to suit your specific testing needs.

Features

-

Hydraulic adjustable upper crosshead to facilitate quick, easy, and accurate positioning with passive clamping system and adjustment by two long stroke actuators.

-

Equipped with integral T-slot platen suitable to fix components, specimens or manufactured assemblies.

-

Chrome plated and hardened columns for easy cleaning and longest life.High quality actuator with hydrostatic bearings for the best static and dynamic performance in different specifications to depending on application.

-

Actuator available with integrated displacement transducer and with anti-rotation system to prevent the natural tendency to rotate.

-

Manifold is attached direct on actuator providing close-coupled servovalve and accumulators for improved performance and reduced pressure fluctuations

-

Precision flat load cell mounted on piston rod end and displacement transducer.

Advanced high performance solution for Static, Fracture Toughness, LCF, Thermo Mechanical Fatigue (TMF), Fatigue Crack Growth and High Cycle Fatigue Testing. Servohydraulic Testing Machine in rigid construction with high axial and lateral stiffness, and precision aligned to satisfy a wide range of different test types.

Multipurpose Dynamic Testing Systems

These machines with its high natural frequency have the actuator integrated in the base of the machine. The alignment fixture is fixed on upper crosshead and provides alignment adjustment of the load string complying with ASTM E1012 and other international standard as required for LCF and other tests. As accessories the alignment verification equipment with stain-gauged specimen (rod), electronic and software is available. This self-supporting unit is optimized for higher frequencies and requires no special foundation. The frame with its movable crosshead by two double acting actuators provides accurate positioning, large and easy accessible test space and allows the integration of fracture toughness bending fixture, environmental or vacuum chamber or high temperature furnace.

Features

-

High stiffness construction, precision aligned

-

Movable upper crosshead for facilitate quick, easy, and accurate positioning by two long-stroke actuators

-

Passive clamping system

-

Inductive hardened, grounded and chromium plated column

-

Double ended, equal area linear actuator with hydrostatic bearings for the best friction free static and dynamic performance, allows high side-loads and emergency running, integrated in machine’s base to shorten the force train.

-

Integrated LVDT displacement transducer

-

Servovalve with manifold mounted direct on the actuator for the highest possible response and most accurate test control

-

Close coupled accumulators to minimize hydraulic pressure fluctuations and filter is mounted direct at the actuator

High precision fatigue rated flat load cell for static and fatigue tests fixed on upper crosshead

Versatile and compact test systems configurable to meet the demands of modern testing laboratories, R & D centers, institutes and universities. The Series LFV - L tabletop systems are currently available in with force capacities ranging from 1 kN up to 25 kN.

Table-Top Dynamic Testing Systems

These fatigue rated systems represents the ideal solution to perform a large variety of static and dynamic materials tests. This series is well suited to perform static tension, compression, flexure and shear tests, LCF - low cycle fatigue testing, fatigue crack growth testing, fracture toughness testing, further typically applications includes testing of biomechanical products and implants and more. The load frame features rigid designed with high axial and lateral stiffness with high natural frequency. The upper crosshead is mechanically clamped and features automatic, motorized, positioning (lifting/lowering). Integrated in the upper crosshead is the fatigue rated actuator with co-axially mounted displacement transducer. The manifold with servo valve is mounted direct on the actuator for the highest possible response and most accurate test control. The close coupled accumulators minimize the hydraulic pressure fluctuations. The fatigue rated, low-profile, low mass designed precision load cell features high natural frequency and excellent long term stability. The LFV-L is available with the alignment fixture for the adjustment of load string alignment complying with ASTM E1012 or other standards. It is capable to perform alignment adjustments while the load train is fully preloaded. As accessory the alignment verification equipment with strain-gauged specimen, electronic and software is available. The system is supplied with the state-of-the-art machine base. As space saving system the solution with integrated hydraulic power pack up to 6 l/min. oil flow is available. Otherwise the machine is supplied with the low noise free standing hydraulic power pack Series PAC. To meet the full range of mechanical testing needs the LFV-L can be configured with a variety of grips and fixtures, extensometers, environmental chambers, different software packages and other accessories. The LFV-L is also available with axial/ torsional drive, upgrading your system from axial only to axial/torsional performance. Standard ratings are 20, 50, 100 and 200 Nm. The torsional angle can be chosen to meet your specific testing needs.

Specially designed for the experimental determination of mechanical properties of materials, components or products subject to combined axial and torsional loading. Available with customized torsional moment, angle and frequency range upgrading your system from axial only to axial / torsional performance.

Dynamic Biaxial Testing Systems

Since no standard testing method exist for multiaxial fatigue testing, it is important to choose a testing method suitable for a purpose of each testing. Due to that fact, beside to the standard axial loadings the torsional drive can be added to the full line of the multipurpose dynamic Testing Machines Series LFV with customized torsional moment, angle and frequency range to suit your specific testing needs.

The Series LFV-T of biaxial fatigue testing machines can torsion loading be coupled with tension-compression. Both torsion and tension-compression can be loaded independently in phase or out of phase. With related accessories the Series LFV-T of testing machines allows to perform a wide range of mixed-mode fatigue testing on rectangular plate specimens, cruciform specimens, three-point and four-point bending specimens with a crack, compact tension shear specimen, compact shear specimen, mode II crack growth specimen, circumferentially notched cylindrical specimens, tubular specimen containing a slit, solid cylindrical specimen containing a small hole or initial crack, tubular specimen for triaxial fatigue testing by applying internal or external pressure and a lot others.

Features

-

Double ended, equal area linear actuator with hydrostatic bearings for the best friction free static and dynamic performance, allows high side-loads and emergency running, integrated in the upper or lower crosshead to shorten the force train. With displacement transducer.

-

Dynamic rated torsion drive closed coupled to the axial actuator

-

High precision angle transducer.

-

One-chamber-design, High stiffness construction, precision aligned, inductive hardened, grounded and chromium plated columns.

-

Servovalve manifold platen mounted direct on the actuator for the highest possible response and most accurate test control.

-

Close coupled accumulators to minimize hydraulic pressure fluctuations

-

High precision fatigue rated biaxial load cell for static and fatigue tests fixed on the upper crosshead, lower t-slot base platen or piston rod end for testing of components