R.C. TECHNOLOGY

RAMLA CONSTRUCTION TECHNOLOGY

مؤسـسة الرمـــــلة لتقــنية البناء

" Your Partner in Success "

Static Universal Testing Machines

Our Products

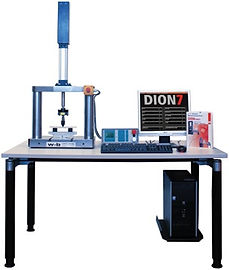

Series LFM - L 0.5 - 20 kN

Single column, table top universal testing machines for low load capacities up to 20 kN.Ergonomically designed testing machines for tensile, compression, bending, sheer or peel but also strain and other more advanced tests on a wide range of different materials.

Electromechanical Low-Capacity Testing Machines

The LFM-L Series of Universal Testing Machines are designed for testing of a variety of different materials, specimens or components where load requirements are low. This series is compatible with a wide range of accessories, grips and fixtures covering all relevant applications as testing of rubber, plastics, foils, films, textiles, adhesives, paper, foods, foams, timber, wires or other metallic or non-metallic specimens and medical, electronic and other components. The load frames are rigid constructed, providing superior axial and lateral stiffness. The linear module with multiple guided, backlash-free ball screw assembly with anodisedaluminium frame combines high performance with compact dimensions. Available also as horizontal machines for testing of extra-long specimen in ergonomically working height.

The LFM load frames are rigid constructed, providing superior axial and lateral stiffness. The two linear modules with anodisedaluminium frame are precise systems that combine high performance with compact dimensions. The linear modules are protected by corrosion-resistant steel strips which are easy to clean and also resistant against high temperature.

Series LFM - C 0.5 - 40 kN

The ideal solution for testing applications with small or medium displacements as compression, bending or sheer testing.

Compact Electromechanical Table-Top Testing Machines

The frame of the Series LFM-C of testing machines features a central ball screw electro-thrust cylinder assembly that also allows very short movements due to the absence of stick-slip effects. The inline mounted drive with motor provides high responsive control with minimum backlash. The frame features very high stiffness with a lower T-slot platen suitable to fix grips or fixtures, components, specimens, manufactured assemblies or finished goods. The crosshead is available in fixed position or movable with manual clamping. Suitable grips or fixtures can be mounted quick and easy onto the standard spigots with pin or onto the T-slot platen.

Series LFM 20 - 125 kN

The LFM Series are "State-of-the-Art" Testing Machines using the latest technology providing uncompromised quality, accurancy and reliability. Due to our large accessory programm they can be used for almost any testing application in the field of strength and deformation of specimen and components.

Elektromechanical Universal Testing Machines

The LFM Testing Machines are mostly the choice of this in the metals, fastener, composites, wood, geotextile, cable, forging, adhesive and civil industries or in R&D laboratories and universities where specimen size and strength require higher force capacities. This series of testing machines are driven by a high responsive AC brush less servomotor with high startup torque. The backlash-free ball screws providing high load capacity, high positioning accuracy and repeatability. The lower base platen is also available with T-slots suitable to fix components, specimens, manufactured assemblies or other accessories. These material testing systems are available with different standard configurations. All options as extended lateral test space for mounting of high temperature furnaces or environmental chambers, other crosshead travels, additional low force transducers etc. are available. The machine is equipped with multi-position limit detectors for the best protection of operator, test sample and machine.

Series LFM - H 150 - 1500 kN

The LFM-H high-capacity testing machines are mainly used for testing of metals, fastener or composites and also in research and development where specimen size and strength require higher force capacities.

Electromechanical High-Capacity Testing Machines

The Series LFM-H testing machines often are the perfect solution for typical applications including testing of large metal specimens, fasteners, composites, cables, forgings, welded joints, geotextiles, polymers and reinforced plastics, civil structure materials, adhesives, components or finished goods. The machines with its pre-loaded, backlash-free ball screws and heavy duty bearings with additional robust guidance columns features accurate crosshead alignment and are suitable not only for tension or compression test but also through zero testing. The backlash-free ball screws are digital controlled by a high responsive AC brush-less servomotor with high start up torque for faster starts and stops and best and most accurate control over a large speed range at a extremely low noise level. These load frames are rigid 4-column constructions, providing superior axial and lateral stiffness. The machine is equipped with multi-position limit detectors for the best protection of operator, test sample and machine. The load frame is constructed in the way that the upper crosshead is driven so that the lower base platen remains and allows an ergonomic working in seated or standing position at pleasant working height. The lower base platen is also available with T-slots suitable to fix components, specimens, manufactured assemblies or other accessories. Optional are 2nd and 3rd test chambers and operators safety protection when brittle materials are tested.

Series LFMZ 20 - 600 kN

The Series LFMZ of testing machines is the perfect solution for creep, relaxation or LCF testing. Special software packages for data acquisition of single or multiple machines with force, elongation, and temperature and time registration with graph fulfill the requirements of modern testing laboratories.

Electromechanical Central-Spindle Testing Machines

The Series LFMZ of testing machines feature a special torsion and backlash-free pre-stressed central ball screw drive by a brush-less-free AC servomotor. The machine also allows long term tests with only small deformations and is therefore mostly used to perform creep fatigue (constant applied load), relaxation (constant elongation) or LCF (low cycle fatigue) test under certain temperature conditions with high temperature furnace. Compared with dead weight or spring loaded systems the Series LFMZ testing machines are fully programmable and offer closed loop force, deformation or crosshead control with testing speeds as low as 0.5 micron / hour. These testing machines can be also used for tensile, compression or 3- / 4-point bending tests for example on ceramic specimens or with built in environmental chambers.

Series TTM® 100 - 4500 kN

TTM® Tensile Testing Machine is a registered trademark of walter+baiag Testing Machines.

The Series TTM testing machines are “state-of-the-art”, rugged and durable designed especially suitable for high capacity testing of round, flat and profile specimens meeting the needs of the metal, aerospace, automotive and fasternindustries.The economic solution mainly in the field of higher and highest capacity testing.

Servohydraulic Universal Testing Machines

The Series TTM testing machines with its single test space designed for tension, compression, bend and folding, shear and static cyclic testing is specifically suitable for testing of metals-(wire, rod, tube, strip, plate, strip), fasteners (tensile, proof, single and double shear), construction materials (reinforcement bar, wire, mesh, folding, compression of concrete) and components. All models of the Series TTM feature a rigid load frame either in two- or four-column construction for minimum maintenance and low reaction at specimens failure. The servo-actuator, which is integrated in the upper crosshead with a long piston stroke makes testing space accessible for easy and efficient testing of different samples lengths. The high precision load cell is located between base platen and lower grip, providing high accuracy test after test. The servoactuator, which is integrated in the upper crosshead, has a long piston stroke which makes testing space accessible for easy and efficient testing of different samples lengths. The long piston stroke meets the extreme requirements of international standards without changing the crosshead adjustment. On piston rod end a anti-rotation system prevents the natural tendency of the actuator to rotate. Ergonomically design with unchanged height of lower grip and accessible test space for easy and efficient testing. With chrome plated columns for easy cleaning and longest life

Series LF(SV) 50 - 1000 kN

The Series LF and LFSV of servo-hydraulic testing machines are compact designed and therefore especially suitable for laboratories with reduced ceiling heights. LF models with mechanically clamped and movable upper cross-head; LFSV models with hydraulically movable upper cross-head.

Servohydraulic Universal Testing Machines

The LF(SV) testing machines are ergonomically designed floor standing machines for tensile, compression, bending or shear but also strain and other more advanced tests on a wide range of different materials. The Series LF and LFSV cover the same application range as the Series TTM. Compared with the Series TTM, the double-acting actuator is integrated in the base of the testing machine what results in a very compact design and reduced machine height. The LFSV Models feature a hydraulically movable upper crosshead through two long stroke actuators for quick, easy and accurate re-positioning. The LF Models instead feature a mechanically clamped and movable upper crosshead. The Series LF and LFSV Testing Machines are modular constructed and can be configured with a variety of grips and fixtures, extensometers, different software packages and other accessories to suits your specific testing needs. To meet the wide variety of testing needs, the LF (SV) is offered in different configurations. All options as: extended test space or distance between columns, other actuator strokes, protection device for operators safety, additional low force transducers a.s.o are available. The precision load cell, which is mounted on crosshead, is overload protect